What does Thorough Examination cover?

The following is a guide to what a Thorough Examination of a counterbalance fork lift truck includes. Other types of lifting equipment may vary in what the test covers.

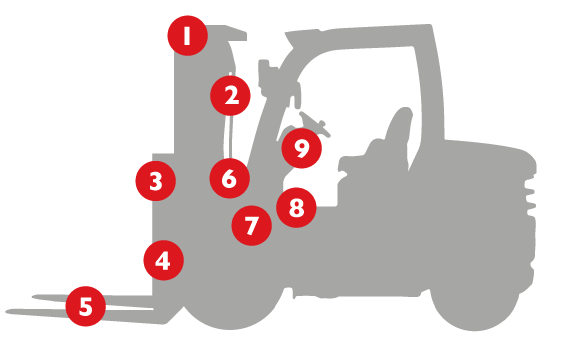

LOLER (lifting parts)

- 1The mast or telescopic boom must be inspected throughout its full range of movement. The hydraulic systems are also inspected and tested.

- 2Chains are checked and measured, a change of just 3% will mean they must be replaced. Pulleys and anchors points are also inspected.

- 3The load backrest is inspected to make sure it is structurally sound and securely mounted.

- 4The fork arm carrier is checked for cracking and distortion.

- 5Forks are checked for wear, cracking, distortion and splaying. Forks must be of the correct capacity.

- 6The tilt mechanism is checked for a controlled and even movement and for signs of scoring and damage.

- 7The hydraulic system is also inspected, this includes cylinders, reservoirs, pipes, hoses and filters.

- 8Capacity rating plates must be securely attached and legible. It must show the capacity rating for the truck and any attachments fitted.

- 9The controls including cables and linkages are tested for correct operation and damage or corrosion. They must be securely mounted and their function clearly marked.

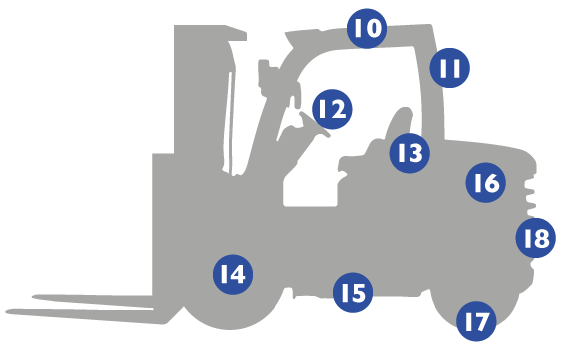

PUWER (other parts)

- 10The cab or overhead guard is checked that it is securely mounted and structurally sound. Transparent screens must be clear and undamaged.

- 11All safety systems are checked to make sure they function correctly. These include visible and audible warning devices, capacity data plates and safety interlocks.

- 12Steering mechanical and hydraulic components are checked for damage, wear and corrosion. Steering operation is also tested.

- 13Seating restraints including seatbelts are checked for wear, damage and secure mounting. Seat mounting is also checked.

- 14Services and parking brake systems are checked and tested. The test covers hydraulic/pneumatic systems, mounting, cables, linkages, pedals, levers and controls.

- 15The chassis is checking for signs of damage and cracking in welds.

- 16The prime mover, transmission and exhaust are checked on diesel and LPG trucks, batteries and connections on electric trucks.

- 17Wheels are checked for condition and secure fixing. Tyres are checked for specification, wear, damage and bonding failure. Wheel bearings are also checked.

- 18Counterweighting is inspected for security and damage.

Does your Lifting Equipment need Thorough Examination?

We are CFTC accredited.

We carry out LOLER Thorough Examination on:

We carry out LOLER Thorough Examination on lifting equipment.

Telehandlers

Tail Lifts

Reach Trucks

Personnel Lifts

Loaders

Fork Lift Trucks

Cherry Pickers